Brochure Concrete treatment

Please find further information on our INOCOT products for the treatment of concrete surfaces.

Refined. For you.

At a glance

LONG-LASTING PROTECTION

Untreated concrete is susceptible to moisture, dust and stains, over time it can change its texture. Our INOCOT products cause the surface to harden and densify by means of a chemical reaction. INOCOT impregnates the surface instead of just coating it, providing long-lasting protection for concrete floors. A floor treated with INOCOT can never blister.

BRILLIANT SURFACES

Floors treated with INOCOT are beautiful and modern. Sanding and polishing gives them a glossy surface, the shine of which increases with each cleaning. The surface finished with INOCOT does not show dust formation and scratch marks, which are common with coatings.

EASY APPLICATION

The use of our INOCOT products is very simple. They can be sprayed or poured onto the concrete and then spread. A treated surface can be walked on again after only two hours. It is not necessary to wait until it is completely dry. With INOCOT, a glossy surface can be created only by grinding and polishing.

COST-EFFICIENT

Our INOCOT products are extremely cost-efficient. Very little product is needed for the treatment (max. 0.5l / m2). At the same time, the effect of the product is extremely long-lasting. No repeated treatment is required and hardly any time is lost, as there is no need to wait for complete drying before further processing.

EASY CLEANING

A floor finished with INOCOT is easy to keep clean. Small pores are impregnated, small cracks are bridged so that dust and dirt cannot accumulate.

SUSTAINABLE ALTERNATIVE

Our INOCOT products are inorganic, non-toxic or allergenic and do not emit organic micro-dust. They are absolutely harmless throughout their lifetime.

See for yourself

INOCOT for existing floors

INOCOT 601 is a lithium sealer that forms a microfilm on polished concrete and other cementitious surfaces.

INOCOT for new floors

INOCOT 611 is a penetrating lithium stain protector. It creates a protective barrier that strengthens the concrete matrix.

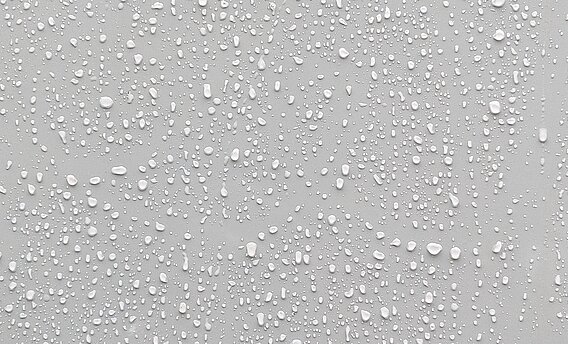

Untreated concrete in wet conditions

Untreated concrete floors absorb moisture upon contact with water.

Hydrophobic concrete floors: INOCOT 608H & 618H

INOCOT hydrophobized products prevent the penetration of liquids into the surface of the concrete while retaining all other benefits.

INOCOT 608 H is the hydrophobized version of INOCOT 601. INOCOT 618 H is the balanced hydrophobized version of INOCOT 611.

Product overview

| Product | Product type | Application | Advantages |

|---|---|---|---|

| INOCOT 601 | Lithium-based silicate | All types of floors |

|

| INOCOT 611 | Lithium silicate | High density and new concrete surfaces |

|

| INOCOT 602 | Lithium-based silicate | All types of floors |

|

| INOCOT 612 | Lithium silicate | High density and new concrete surfaces |

|

| INOCOT 608 H | Lithium-based silicate | All types of floors |

|

| INOCOT 618 H | Lithium silicate | High density and new concrete surfaces |

|

| INOCOT 609 O | Lithium-based silicate | All types of floors |

|

| INOCOT 619 O | Lithium silicate | High density and new concrete surfaces |

|

BRIGHT NEW!

Lower alkalinity and viscosity

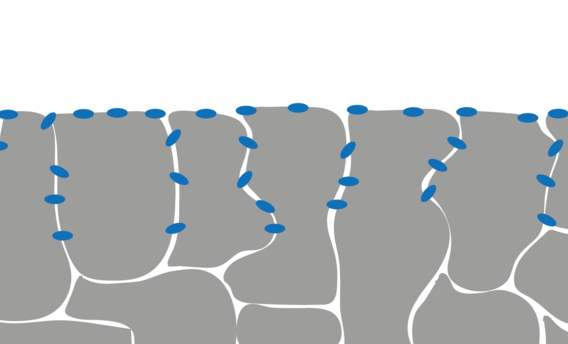

Lithium with its small molecules, lower alkalinity and viscosity compared to potassium and sodium silicates enables more stable and longer reactivity. The application of lithium silicates is much easier, faster and more efficient than standard silicates. Due to the slower reaction and lower viscosity, lithium silicates penetrate the substrate much better and do not require mechanical incorporation.

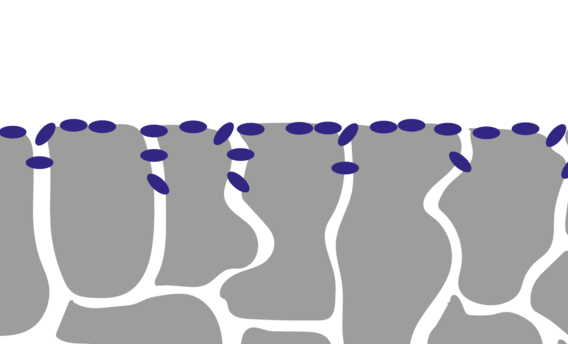

How it works

Our INOCOT lithium silicates act as consolidators, improve the properties and extend the life of the substrate. Treatment with INOCOT lithium silicates makes the surface more resistant to mechanical stress and keeps it visually appealing longer. Due to the deeper viscosity and reactivity, the lithium silicates penetrate deeper into the concrete and thus increase their effect.

Our portfolio for new floors

For the treatment of new concrete surfaces, INOCOT 611 silicates are recommended as a base product. The corresponding ready-to-use products INOCOT 612 as well as hydrophobized INOCOT 618 H and oleophobized INOCOT 619 O complete the range.

NEW AGAIN

Stronger bindings, longer durability

Dusty, cracked or friable floors require a product with stronger binding power. The product should anchor loose particles in the substrate, create a reinforced surface and eliminate fine cracks. The products of the INOCOT range do not form a layer on the surface, but penetrate and impregnate the substrate.

How it works

Our lithium-based INOCOT products are fast-drying sealers that create a microfilm on polished concrete, stone, terrazzo, masonry and other cementitious surfaces. This easy-to-apply finish increases gloss, enhances color and improves resistance to abrasion, chemicals and stains. This non-toxic solution is ideal for solid colored, stained and stained concrete surfaces.

Our portfolio for existing floors

For the treatment of existing concrete surfaces, silicates of the type INOCOT 601 are recommended as a base product. The corresponding ready-to-use products INOCOT 602 as well as the hydrophobized INOCOT 608 H and the oleophobized INOCOT 609 O complete the range.

Application

Our concrete treatment products of the INOCOT range are easy to apply. Clean the substrate - apply product by spraying, pouring or rolling - let dry - done! Of course, you can change the appearance by grinding, polishing and - depending on the desired effect - reapplying as desired.

Dilution and storage

For the concentrated products, it is mandatory to dilute to the required active ingredient content before application (dilution 1:1 with water). Depending on the type of substrate, 0.2 - 0.4 kg/m2 are required. INOCOT should be stored only at temperatures between +5°C and +40°C. The equipment used for the application of INOCOT must be well cleaned with water after use. Once the product has dried out, it can only be removed mechanically.

Technical support

If required, our experts will be happy to support you in all matters relating to concrete treatment with silicates.

If you also require support in the area of research and development, we will be happy to assist.

Contact

Simon Grossmann

Head of Sales OMB