Brochure Silicate paints

In our segment brochure, you can find out what we have to offer our customers in the area of binders for silicate paints.

The future is colorful!

Together with renowned research partners, we have combined the advantages of silicate paints with those of standard dispersion paints. The result is OMB, our Organo-Mineral Binder, a hybrid binder with organic and mineral polymers that creates a physicochemical bond between the organic and mineral molecules. OMB is a highly flexible binder that is completely biocide-free, easily resists water and UV radiation, and adheres equally securely to mineral and organic substrates.

The bond between the two types of polymers provides very good flexibility and high liquid water resistance, while not compromising water vapor permeability. Due to the low Tg acrylic polymers used, no coalescing agent is required in the formulation of the paint and the final binder does not contain any biocides. Also, no additional preservation is needed in the formulation of the paint system.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/c/csm_cam-morin-655393-unsplash__1__2b5164af3b.jpg)

At a glance

Biocide-free

OMB is formulated completely biocide-free. Addition of preservatives in the paint formulation is not necessary.

Adhesion

On mineral and organic substrates: ISO 0 / ASTM 5B.

Water impermeability

OMB reliably prevents the penetration of liquid water: W24 0.023 (DIN EN ISO 1062-3)

UV-resistance

Even after more than 500 hours of direct sunlight, OMB-based inks show hardly any color changes.

Flexibility

OMB achieves 100% magnification at 3.0 MPa.

Dirt pick-up

Excellent resistance to dirt pick-up

Reaction to fire

Flame retardant (class B1-s1,d0 according to EN 13501-1 classification report)

Sustainability

About 20% of the polymer content consists of sand-based mineral polymers and are therefore completely ecologically harmless.

The future is OMB!

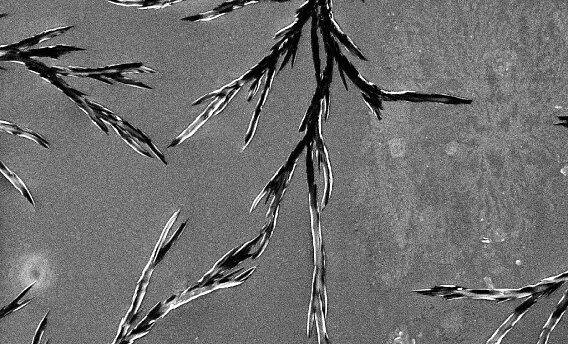

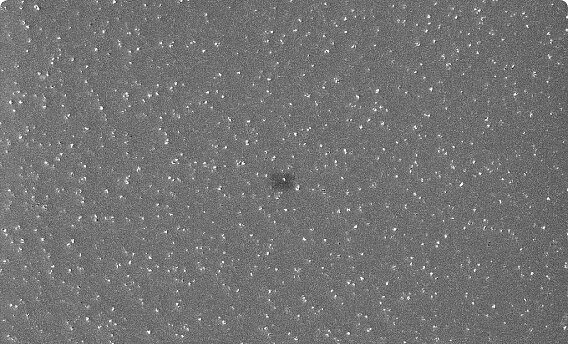

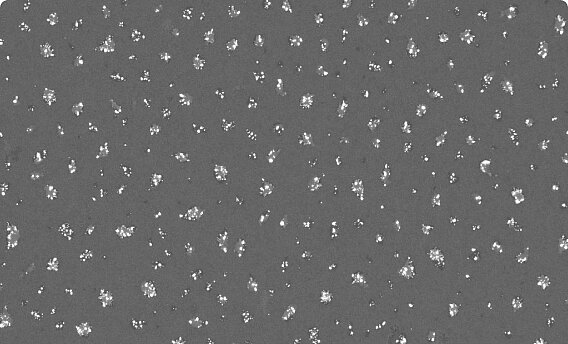

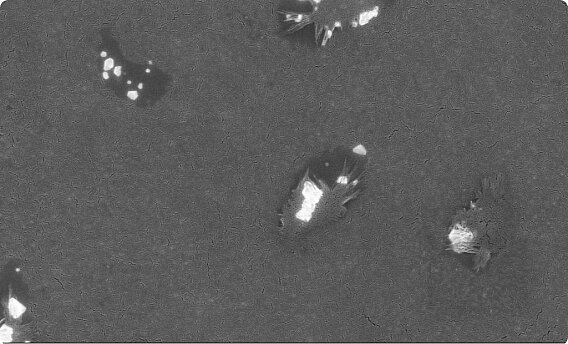

If you look closely, you can see the different steps in the development of OMB:

Standard mixture

The 4000x magnification shows a mixture of styrene acrylic polymer and standard silicate as used in the paint and varnish industry. The mineral polymer (dark), which forms a brittle, glass-like domain, is clearly visible.

Compatible polymers

As can be seen in the picture (enlarged 4000 times), great progress in homogeneity has already been achieved by adapting the mineral polymer.

OMB technology x4000

The image (enlarged 4000 times) shows the final hybrid organo-mineral binder, which consists of an acrylic polymer combined with a mineral polymer.

OMB technology x5000

When enlarged again (5000x), the homogeneity of the hybrid organo-mineral binder is clearly visible. OMB combines the two technologies in a binder that can be used alone or in combination with other compatible organic polymers.

The new technology

Properties | OMB 128 | OMB 130 | OMB 131 | OMB 133 |

|---|---|---|---|---|

Solid content [% by weight] | 48.0% | 46.50% | 45.20% | 45.30% |

Minimum film forming temperature | 2°C | 2° C | 2° C | 2° C |

| pH value | 11.0 - 11.5 | 11.0 - 11.5 | 11.0 - 11.5 | 11.0 - 11.5 |

| VOC [ppm] | < 3'000 | < 1'000 | < 3'000 | < 1'000 |

| Density [20°C] | 1.08 | 1.08 | 1.08 | 1.08 |

| Viscosity [20°C] | 60 - 120 mPas | 60 - 120 mPas | 40 - 120 mPas | 40 - 120 mPas |

Convincing test results

To pre-test the dirt pick-up resistance (according to UNI 10792 standard), we compared a paint based on our INOCOT OMB technology with a paint widely available in Europe.

The two paints were applied by machine and dried under the same conditions (1 week at room temperature).

The quick test itself is carried out with a supsension of black iron oxide (15%).

See for yourself!

Watch on YouTube!Test results

Due to the unique technology combination of mineral and organic polymers, paints based on INOCOT OMB offer decisive advantages in fire behaviour.

We wanted to prove this with a quick test. For this purpose, dry films were made of an OMB-based paint and an acrylic paint and their fire behaviour was compared.

See for yourself!

Shape the future

With our team of coating experts, we are happy to provide you with support. We create guide formulations for a wide range of product types and requirement profiles, formulate paint formulations tailored to your needs and are also available on site for technical support.

Never stop improving

At the moment, our OMB technology is focused on Architectural Coatings. However, we all know that development in the paint sector is never complete.

We are already thinking about where the journey with OMB could go and where further areas of application lie.

Do you have an idea? Do you think OMB could help you solve your problem?

Get in touch with our experts!

Contact

Simon Grossmann

Head of Sales OMB

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/3/csm_Caroline_Dorcier_d088e5eddc.jpg)

Caroline Dorcier

Head of R&D Laboratory

Downloads